Kitchen Cabinet Building Plans: A Comprehensive Guide

Constructing kitchen cabinets can be a rewarding endeavor, allowing for customization to specific spatial constraints, aesthetic preferences, and storage needs. Effective planning is paramount for a successful outcome. Kitchen cabinet building plans serve as the blueprint, guiding the entire construction process from initial design to final installation. These plans encompass a variety of elements, including detailed measurements, material lists, construction techniques, and finishing specifications.

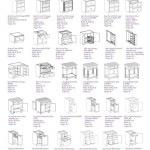

Before embarking on the construction phase, a thorough understanding of the different types of kitchen cabinets is essential. Base cabinets, the foundation of the kitchen, are typically placed on the floor and support countertops. Wall cabinets, mounted on the wall, provide additional storage space and are often used for storing dishes, glassware, and other kitchen essentials. Tall cabinets, also known as pantry cabinets, offer vertical storage solutions and are suitable for storing food items, appliances, or cleaning supplies. Each cabinet type demands specific design considerations and construction methods, which must be accurately reflected within the building plans.

The precision and clarity of kitchen cabinet building plans directly influence the project's efficiency and the quality of the finished product. Inadequate or inaccurate plans can lead to costly mistakes, wasted materials, and ultimately, disappointing results. Conversely, well-defined plans streamline the construction process, minimize errors, and ensure that the final cabinets meet the desired specifications. A comprehensive set of plans should include detailed drawings, material lists, cut lists, step-by-step assembly instructions, and finishing guidelines.

Key Point 1: Developing a Detailed Design and Measurement Strategy

The initial stages of creating kitchen cabinet building plans involve meticulous measurement and design. This process requires a comprehensive understanding of the kitchen's layout and existing structural elements. Precise measurements of the kitchen space, including wall heights, floor dimensions, and the location of utilities (plumbing, electrical outlets), are critical for determining cabinet dimensions and placement. These measurements will dictate the overall size and configuration of the cabinets, ensuring a proper fit within the allocated space.

Once accurate measurements are obtained, the design phase can commence. This involves determining the desired style, functionality, and storage capacity of the cabinets. Factors to consider include the type of cabinet doors (e.g., raised panel, shaker, slab), the hardware to be used (e.g., hinges, handles, drawer slides), and the internal organization features (e.g., shelves, drawers, pull-out organizers). Sketching out the design and creating a 3D model can be invaluable for visualizing the final product and identifying any potential design flaws before construction begins.

It is crucial to translate the design into detailed drawings that specify the dimensions of each cabinet component. These drawings should include top views, side views, front views, and detailed cross-sections, providing a comprehensive understanding of the cabinet's construction. All dimensions should be clearly labeled and accurately represented to avoid confusion during the building process. Furthermore, the drawings should indicate the type of joinery to be used, such as dadoes, rabbets, or mortise and tenon joints, as well as the location of screws, dowels, or other fasteners.

Computer-aided design (CAD) software can significantly enhance the accuracy and efficiency of the design process. CAD programs allow for precise drafting, 3D modeling, and the generation of detailed cut lists. These programs can also simulate different design options and identify potential conflicts, such as interference with existing utilities or structural elements. While CAD software may require a learning curve, the benefits it offers in terms of accuracy, efficiency, and the ability to visualize the final product make it a worthwhile investment for serious cabinet builders.

Key Point 2: Material Selection and Cut List Optimization

The selection of appropriate materials is a critical aspect of kitchen cabinet building. The choice of materials directly impacts the durability, aesthetics, and overall cost of the cabinets. Common materials used for kitchen cabinets include plywood, particleboard, medium-density fiberboard (MDF), and solid wood. Each material possesses unique properties and characteristics that make it suitable for different applications.

Plywood is a versatile and durable material that is commonly used for cabinet boxes and shelves. It offers good strength and stability, and it is less prone to warping or twisting than solid wood. Particleboard is a more affordable option, but it is less durable and more susceptible to moisture damage. MDF is a smooth and uniform material that is ideal for painted cabinet doors and drawer fronts. Solid wood offers a premium look and feel, but it is more expensive and requires careful selection to avoid warping or cracking.

Once the materials have been selected, a comprehensive cut list must be generated. The cut list specifies the dimensions and quantity of each cabinet component, ensuring efficient use of materials and minimizing waste. The cut list should be organized in a logical manner, grouping similar-sized pieces together to streamline the cutting process. Optimizing the cut list is essential for minimizing material waste and reducing the overall cost of the project. Online cut list optimizers can assist in this process, automatically generating the most efficient cutting layout based on the dimensions of the available material.

In addition to the main cabinet components, the material list should also include all necessary hardware, such as hinges, handles, drawer slides, screws, and fasteners. The selection of appropriate hardware is crucial for the functionality and durability of the cabinets. High-quality hardware will ensure smooth operation and long-lasting performance. The material list should also specify the type and quantity of finishing materials to be used, such as paint, stain, varnish, or sealant. The choice of finishing materials will depend on the desired aesthetic and the type of material being used.

Key Point 3: Construction Techniques and Assembly Procedures

The construction techniques employed in building kitchen cabinets directly impact their structural integrity and overall quality. Proper joinery is essential for creating strong and durable cabinets that will withstand years of use. Common joinery techniques include dadoes, rabbets, mortise and tenon joints, and biscuit joints. Each technique offers different levels of strength and complexity, and the choice will depend on the specific application and the builder's skill level.

Dado joints involve cutting a groove into one piece of wood to receive the edge of another piece of wood. This technique is commonly used for joining cabinet sides and shelves, providing a strong and stable connection. Rabbet joints are similar to dado joints, but the groove is cut along the edge of the wood. This technique is often used for joining cabinet backs and sides. Mortise and tenon joints are a more complex joinery technique that involves creating a projecting tenon on one piece of wood that fits into a corresponding mortise (hole) on another piece of wood. This technique is known for its strength and durability and is often used for joining cabinet frames.

Accurate assembly is crucial for ensuring that the cabinets are square, level, and plumb. Before assembling the cabinets, it is essential to dry-fit all the components to ensure that they fit together properly. This allows for any necessary adjustments to be made before applying glue or fasteners. When assembling the cabinets, it is important to use clamps to hold the components together while the glue dries or the fasteners are driven in. Clamping ensures a tight and secure bond, preventing gaps or misalignment.

After the cabinets have been assembled, they should be carefully inspected for any imperfections or defects. Any necessary repairs or adjustments should be made before proceeding with the finishing process. This may involve sanding down rough edges, filling in gaps with wood filler, or replacing damaged components. Taking the time to address any imperfections at this stage will ensure a professional and long-lasting finish.

The final step in the construction process is the installation of hardware, such as hinges, handles, and drawer slides. The hardware should be installed according to the manufacturer's instructions, ensuring proper alignment and smooth operation. The installation of hardware should be done with care to avoid damaging the cabinet surfaces. Once the hardware has been installed, the cabinets are ready for finishing.

Proper finishing techniques are crucial for protecting the cabinets from moisture, scratches, and other damage. The type of finish used will depend on the desired aesthetic and the type of material being used. Common finishing options include paint, stain, varnish, and sealant. Before applying the finish, the cabinet surfaces should be thoroughly sanded to create a smooth and even surface. The finish should be applied in thin, even coats, allowing each coat to dry completely before applying the next. Multiple coats of finish may be necessary to achieve the desired level of protection and durability.

Kitchen Base Cabinets 101 Ana White

Build Kitchen Cabinets Free Plans Building Cabinet

Woodsmith Custom Kitchen Cabinets Plans Wilker Do S

21 Diy Kitchen Cabinets Ideas Plans That Are Easy To Build Building Cabinet New

Diy Cabinet Making Your Guide On How To Build A

Kitchen Cabinet Plans Amazing Your Residence Idea Base Cabine Building Cabinets Diy Remodel

How To Build Base Cabinets The Complete Guide Houseful Of Handmade

Kitchen Cabinet Plans Woodwork City Free Woodworking

Kitchen Cabinets The Engineer S Way Finewoodworking

How To Make Cabinets Kitchen Cabinet Plans Building