PVC Board Sheet: A Versatile Material for Kitchen Cabinets

PVC (Polyvinyl Chloride) board sheet has emerged as a prominent material choice in the construction and renovation of kitchen cabinets. Its versatility, durability, and resistance to moisture and pests make it a compelling alternative to traditional wood products. This article details the characteristics, advantages, disadvantages, and applications of PVC board sheets specifically in the context of kitchen cabinet construction.

PVC board sheets are manufactured from a synthetic plastic polymer composed of vinyl chloride. The production process involves polymerizing vinyl chloride monomer to form PVC resin. This resin is then combined with various additives, such as stabilizers, lubricants, and pigments, to enhance its properties and achieve the desired characteristics for specific applications. The mixture is then extruded or calendered into sheets of varying thicknesses and sizes. These sheets can be easily cut, shaped, and assembled into cabinets using standard woodworking tools and techniques.

Advantages of PVC Board Sheets for Kitchen Cabinets

The adoption of PVC board sheets in kitchen cabinetry is largely driven by their demonstrable advantages over conventional materials. These advantages significantly contribute to the longevity, functionality, and overall value of kitchen cabinets.

Moisture Resistance: One of the most significant benefits of PVC board sheets is their inherent resistance to water and moisture. Unlike wood-based materials, PVC does not absorb water, preventing swelling, warping, and rot. This makes it an ideal choice for kitchens, where exposure to moisture is commonplace due to spills, humidity, and cleaning activities. This resistance reduces the risk of mold and mildew growth, improving the overall hygiene and air quality of the kitchen environment. The moisture resistance extends the lifespan of the cabinets, as they are less susceptible to water damage and degradation.

Pest Resistance: PVC board sheets are impervious to insect and rodent infestation. Unlike wood, which can be a food source for termites and other pests, PVC provides no nutritional value and is therefore not attractive to them. This inherent pest resistance eliminates the need for chemical treatments and reduces the risk of structural damage to the cabinets. This property is particularly beneficial in regions with high termite or pest activity, offering long-term protection and reducing maintenance costs.

Durability and Longevity: PVC board sheets are known for their durability and resistance to wear and tear. They are less prone to scratches, dents, and impacts compared to some other materials. The robust nature of PVC contributes to the extended lifespan of kitchen cabinets, ensuring they maintain their structural integrity and aesthetic appeal for many years. This durability translates into reduced maintenance requirements and lower replacement costs over the lifetime of the cabinets.

Ease of Maintenance: PVC board sheets are relatively easy to clean and maintain. Their smooth, non-porous surface resists stains and can be easily wiped clean with a damp cloth and mild detergent. They do not require painting or sealing, further simplifying maintenance. This ease of maintenance contributes to the long-term aesthetic appeal of the cabinets and reduces the time and effort required for cleaning and upkeep.

Design Flexibility: PVC board sheets can be easily cut, shaped, and routed, allowing for a wide range of design possibilities. They can be manufactured in various colors and finishes, or they can be painted or laminated to achieve the desired aesthetic. This design flexibility allows homeowners and designers to create custom kitchen cabinets that meet their specific needs and preferences. The ability to create intricate designs and profiles adds to the visual appeal of the kitchen.

Disadvantages of PVC Board Sheets for Kitchen Cabinets

While PVC board sheets offer many advantages, it is important to acknowledge their potential drawbacks. These limitations should be carefully considered when evaluating PVC as a material choice for kitchen cabinets.

Cost: PVC board sheets can be more expensive than some traditional materials like plywood or particleboard. The initial cost of PVC cabinets may be higher, but this can be offset by their longer lifespan and reduced maintenance requirements. However, the upfront investment should be factored into the overall budget for a kitchen renovation or construction project.

Environmental Concerns: The production of PVC involves the use of chlorine, which is a potential environmental hazard. The disposal of PVC materials can also pose environmental challenges, as they are not biodegradable and can release harmful substances if incinerated improperly. However, advancements in PVC recycling technology are helping to mitigate these environmental concerns. Responsible manufacturing practices and proper disposal methods are crucial to minimizing the environmental impact of PVC.

Heat Sensitivity: PVC board sheets can be susceptible to damage from excessive heat. Prolonged exposure to high temperatures can cause them to soften or warp. It is important to avoid placing hot items directly on PVC surfaces and to consider the proximity of cabinets to heat sources such as ovens and stoves. Proper ventilation and heat shielding can help mitigate this risk.

Aesthetic Limitations: While PVC board sheets can be painted or laminated, they may not have the same natural wood grain appearance as solid wood or wood veneer. Some homeowners may prefer the warmth and character of natural wood over the more uniform appearance of PVC. However, advancements in PVC manufacturing have produced textures and finishes that more closely resemble natural wood, offering a wider range of aesthetic options.

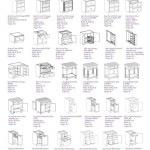

Applications of PVC Board Sheets in Kitchen Cabinet Construction

PVC board sheets can be used in various components of kitchen cabinets, providing a versatile and durable solution for different applications.

Cabinet Boxes: PVC board sheets are commonly used for constructing the cabinet boxes, which form the structural framework of the cabinets. Their moisture resistance and durability make them an excellent choice for this application, ensuring the cabinets remain stable and functional even in humid environments. The consistent thickness and smooth surface of PVC board contribute to the ease of assembly and the overall quality of the cabinets.

Cabinet Doors and Drawers: PVC board sheets can be used for cabinet doors and drawers, either as a substrate for laminates or veneers, or as a finished surface. The ability to create intricate designs and profiles with PVC allows for a wide range of aesthetic options. They offer a stable and durable base for decorative finishes, ensuring the doors and drawers maintain their appearance and functionality over time.

Shelving: PVC board sheets are an ideal material for shelving inside kitchen cabinets. Their strength and resistance to sagging make them suitable for supporting heavy items. The smooth surface of PVC allows for easy cleaning and prevents items from snagging or scratching. They provide a reliable and hygienic storage solution for kitchenware and supplies.

Toe Kicks and Backsplashes: PVC board sheets are often used for toe kicks, the recessed area at the base of the cabinets, and backsplashes, the vertical surface behind the countertop. Their moisture resistance makes them well-suited for these areas, which are often exposed to spills and splashes. They provide a durable and easy-to-clean surface that protects the cabinets and walls from water damage.

In summary, PVC board sheets offer a compelling combination of durability, moisture resistance, and design flexibility, making them a viable option for kitchen cabinet construction. While certain disadvantages, such as cost and environmental concerns, should be considered, the benefits of PVC board sheets often outweigh these drawbacks, particularly in kitchens where moisture and pest resistance are critical requirements. The specific application of PVC board sheets within a kitchen cabinet design should be carefully evaluated based on individual needs and preferences. As technology continues to advance, PVC board sheets are likely to become even more refined and versatile, further solidifying their position as a leading material choice for kitchen cabinetry.

What Are The Pros And Cons Of Pvc Kitchen Cabinets Boardway Plastic Sheet Foam Board Manufacturer

8 14 Mm Pvc Wooden Design Sheet For Kitchen Cabinets From China Manufacturer Jinan Jinbao Plastic Co Ltd

Super Rigidity Board Pvc Co Extruded Foam Sheet For Kitchen Cabinet Furniture Boardway Plastic Manufacturer

Waterproof 10mm 18mmthick Plastic Pvc Sheet For Kitchen Cabinet Made In China Com

Pvc Sheets For Kitchen

Expanded 16mm 0 55 Density Pvc Board Kitchen Cabinets Foam Sheet Made In China Com

Popular Pvc Board Pipes Group Of Companies

The Only Guide To Pvc Kitchen Cabinets That You Need In 2025

The Uses Of Pvc Foam Board In Cabinet Furniture Boardway Plastic Sheet Manufacturer

Expanded Pvc Foam Board For Kitchen Cabinet Interior Decoration Boardway Plastic Sheet Manufacturer